In this CNC post we will look at some basic concepts when machining wood using a CNC machine. Factors such as feed rates, tools, materials (wood types), and machine rigidity will be discussed.

Wood is a rather common material, and a material-category that is relatively easy to CNC machine. Some of the challenges you always have when machining “heavier” materials is overheating if travelling to slow, and tool breaking if traveling to fast. But when machining wood they are not that relevant.

Of course you will touch upon those challenges, but you will not destroy stuff in less than a second (challenge accepted?). You will probably get some “warning-smoke” first…

If you haven’t already, you should read this blog-post where we explain some of the basic concepts leading up to a simple CNC-machining-session.

Feed Rates

When your design is ready for CAM and CNC-ing you need to decide upon a feed rate. This is the machine’s travel speed through the material.

The feed rate is linked to several factors, and the most important of thees are the material, tool and machine.

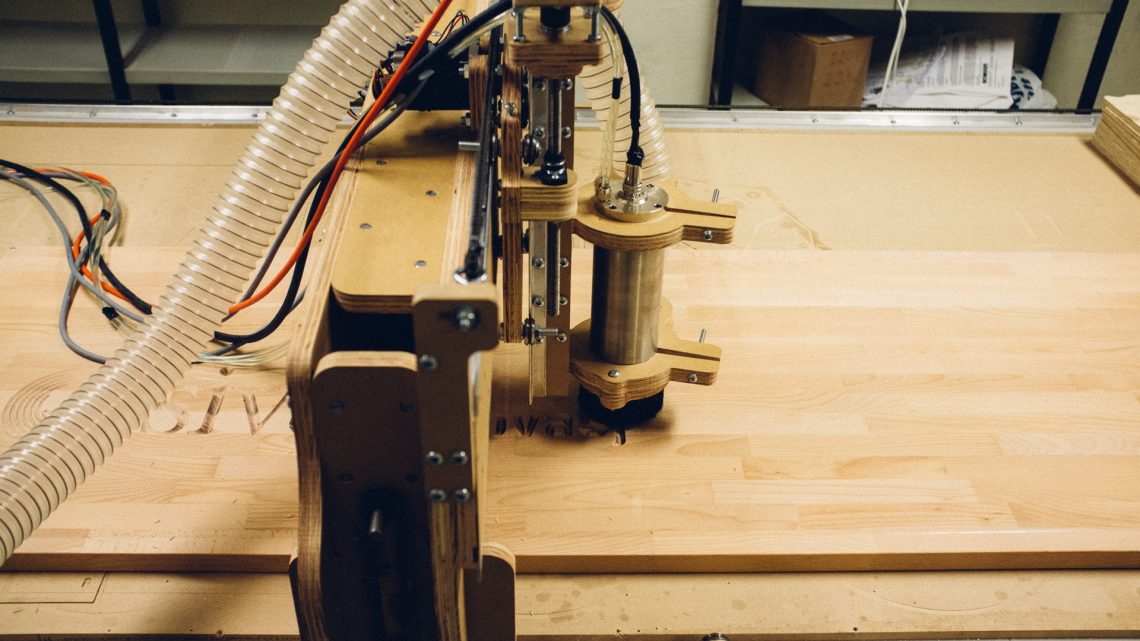

How sturdy is your machine? If you have a high-end CNC-machine that can push several hundreds of kgs, you don’t need to worry about that. But only a few lucky people are in that class.

A symptom of machine weakness is “lost steps“. That is when the motors doesn’t manage to move the spindle, but the machine thought it did (visible on open-loop motion system). It can be several reasons to this, such as motor driver failures, but too heavy machining is a common reason.

You should find/decide an upper limit on feed rate based on machine rigidity.This is machine specific, and CNC machines such as Shapeoko have a rather comprehensive Wiki with materials & speeds here.

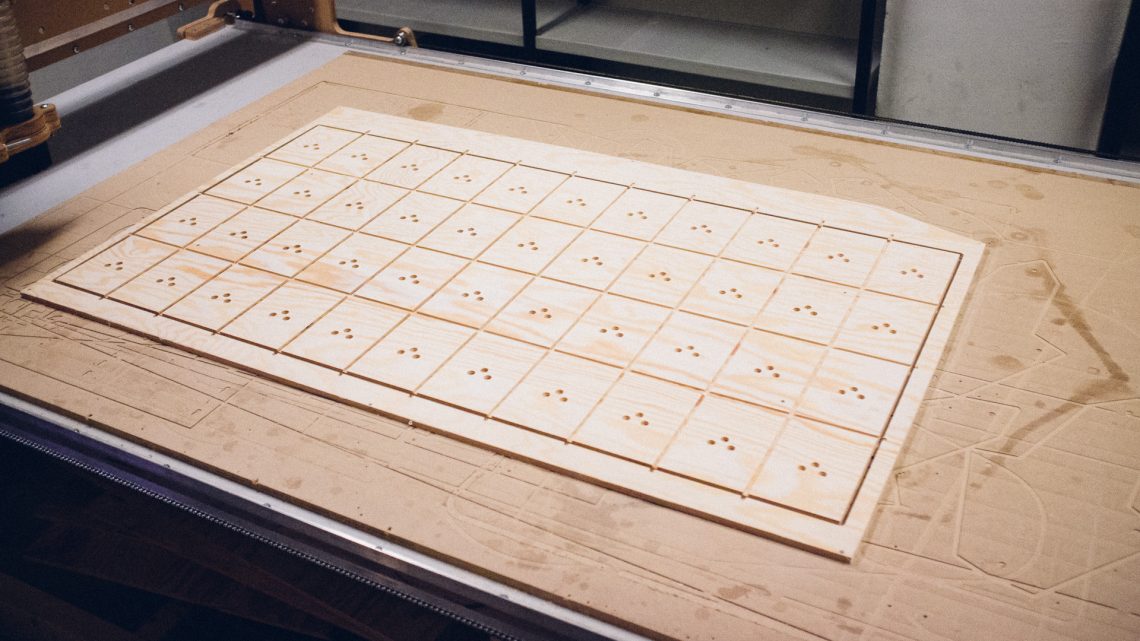

In the picture above we successfully CNC-machined plywood with a depth on each pass (DOC) equal half the tool diameter and a feed rate on 1000 mm/min. This is a rather conservative speed, but it works as a starting point on this kind of machine (a BuildYourCNC blackFoot with a 2.2 kW spindle).

Tools / End Mills

Wood is not as homogeneous as plastics and metals. Every point in the material is connected to surrounding points with different amounts of strengt. With other words:

Wood splinters

Since wood splinters in a (somewhat) random way, you need to take some basic choices when it come to tool geometry:

- Upcut: A tool that ejects the wood chips (the things you are cutting away) upwards. This tool geometry tends to tear the top edge of the material.

- Downcut: A tool that pushes the chips downwards. This leaves a clean top edge, but can cause tear-out on the bottom.

- Straight cut: A tool with almost no angle on the cutting edge. This tool type is a mix of the good and bad with both Upcut- and Downcut-tools. It can both leave you a rather “okey” edge on the bottom and the top edge, but it’s not king of chip ejection. Meaning that it can easily become too hot because it doesn’t manage to remove the chips as good as the two previously mentioned tool types.

- Compression: This tool type is a merge of Upcut and Downcut. It has a couple of millimetres with upcut at the end, while the rest is downcut. So if you mill with a DOC higher than the distance from the tool tip to this transition you will enjoy both a upcut-nice bottom AND a downcut-smooth top edge. Nice!

And remember that tools is a consumable. They get worn out. Blunt tool = bad time.

What the tool is made of is not that important compared to when machining metals, but remember that most of the tools is made for constant active cooling. So they can easily get way to hot when machining in wood since you don’t use any cooling systems. We have successfully machined a lot of wood with carbide tools made for machining in wood.

If your tools is getting a dark edge you know that it has gotten too hot. Reduce the tool heating by either raise the feed rate, slow down the spindle speed or go home. Or change the tool. Maybe it’s getting worn out?

And after you have done a job you can check the tool temperature (remember to turn the machine off first!). It should not be warm.

Materials / Wood Types

“Wood is wood” is wrong

If you have mastered CNC-ing in one plywood type, another plywood of almost the same type will let itself be machined almost in the same way…

Don’t get cocky saying you know how to machine all kinds of wood after you have mastered machining a grandmother-soft MDF-board

It exists many sorts of wood, some which is called hardwood (yes, it’s harder than “regular” wood). They all need their own feeds & speeds.

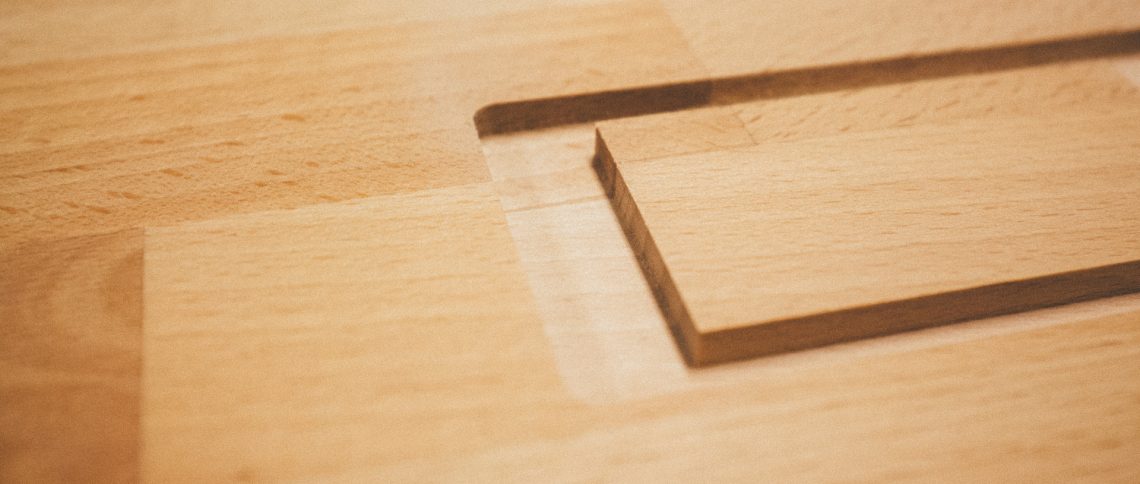

In the image above we machined Beech. That is rather hard. To get perfect machining here we machined at 150 mm/min! And to control the tool heating we had to run the spindle speed super low (7k-ish)!

Stay tuned for the next basic CNC-post! And you can subscribe to our newsletter here to get access to our rather cool monthly update 🙂